Later this year, Boston Dynamics plans to put its all-electric humanoid Atlas robot to work in a Hyundai factory. The new version of the bot, evolved from the hydraulic Atlas model that’s been performing viral video demos since 2013, made its public debut last spring. But while the company’s dog-like Spot and warehouse robot Stretch are already deployed at industrial sites, the Hyundai pilot will be the first time Atlas is used in commercial manufacturing.

Boston Dynamics, which was acquired by Hyundai for $1.1 billion in 2021, is coy about how the robot will be used, but the general idea is that it’s designed to be stronger and more reliable than a human worker. “The robot is going to be able to do things that are difficult for humans,” Boston Dynamics spokesperson Kerri Neelon says. “Like pick up very heavy objects and carry things that are awkward for humans to carry.”

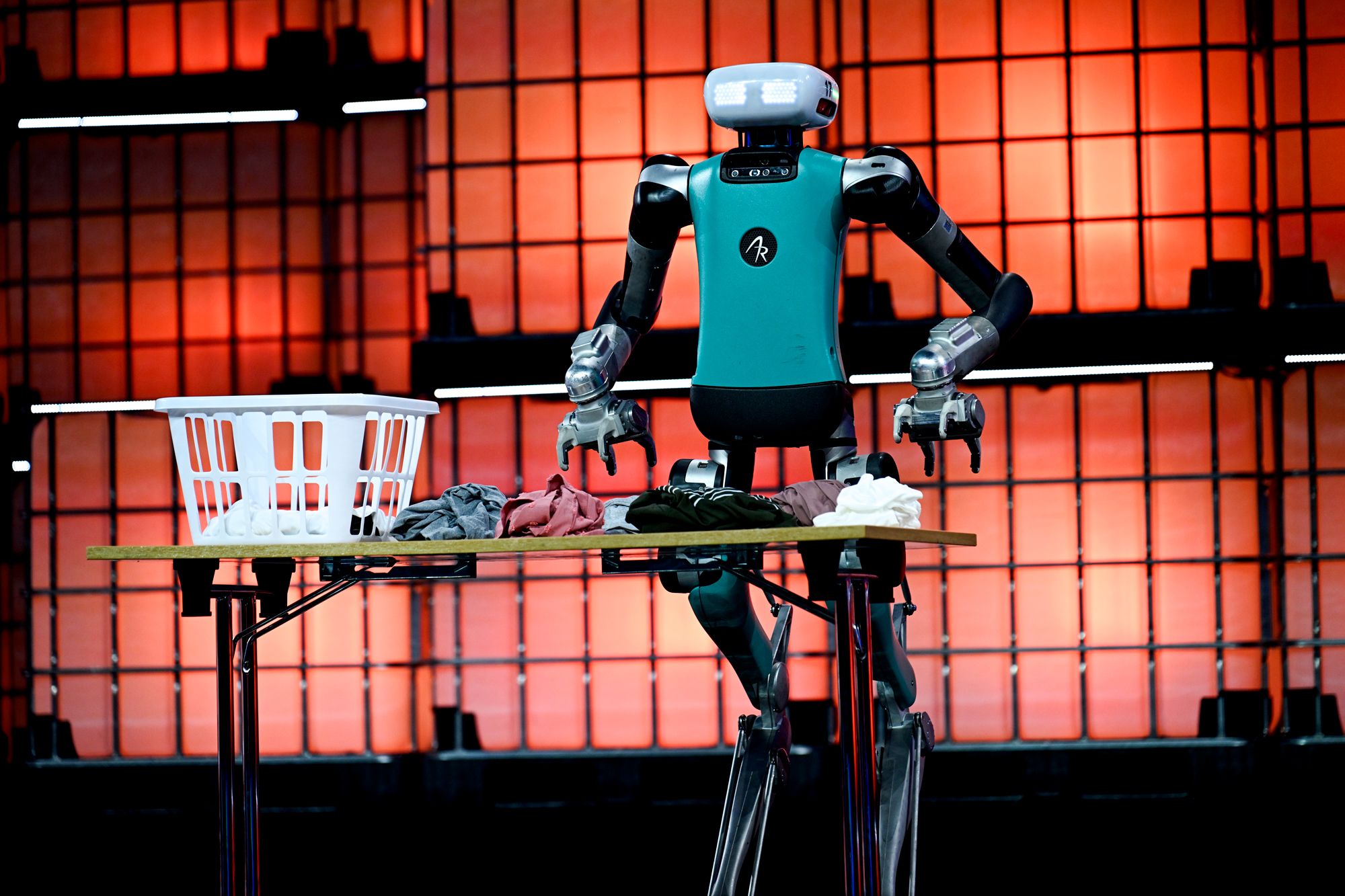

Atlas will have friends: 2025 looks set to be the year that multipurpose humanoid robots, until now largely confined to research labs, go commercial. Some have already taken their first tentative robot steps into paid work, with Agility Robotics’ Digit moving items in a warehouse and Figure’s eponymous biped shipping out to commercial customers last year.

Tech giants are also getting in on the trend: Both Apple and Meta are rumored to be working on some kind of consumer-facing humanoid robot. A 2024 Goldman Sachs report estimates that humanoid robots will represent a $38 billion market by 2035—more than six times what the firm projected a year earlier.

The basic promise of humanoid robots is that they will be able to switch between multiple tasks, just like their human peers. It’s a fundamentally different approach from traditional assembly line automation, which builds an entire environment around the specific tasks required for manufacturing. Jonathan Hurst, cofounder and chief robot officer at Agility Robotics, expects its robots to sit alongside that process, not disrupt it.

“A purpose-built automation solution is always going to be higher performance and lower cost for that purpose,” Hurst says. “That’s great if you have 24/7 operations for that specific thing you want to do.” But for tasks that don’t need to run around the clock, a flexible robot could be more productive.

Boston Dynamics puts it a different way. With factories already designed to be a safe place for automation, the company says it built Atlas with an eye toward making a robot that could go everywhere else. “We live in a human-first world,” Neelon says, “so we should build a robot that reflects that.”

But there are challenges to getting humanoid robots to market. Tesla’s Optimus has been heavily anticipated since the company first announced it in 2021, but a demo in October drew concerns when the robots on display were revealed to be human-controlled, raising questions about the extent to which Optimus could function autonomously. In January, Musk said the company was set to build “several thousand” robots over the course of 2025—but in April he told investors production could be impacted by the restrictions on rare-earth metal exports China implemented in response to President Donald Trump’s tariffs.

One of the biggest roadblocks to making multipurpose humanoids truly useful has been the time it takes to teach robots how to do different tasks. But experts think the huge progress made by large language models could help with that problem. That’s part of the reason humanoid robot projects are emerging at companies like Apple, Meta, and Tesla, which already have thriving AI labs. In March, Google DeepMind released a new AI model called Gemini Robotics with just this application in mind, using the adaptability of a large language model to make robots better at adapting to new situations.

Once robots have the ability to learn skills on the fly, they’re better equipped to switch from task to task like a human worker. “You can imagine a grocery or tractor supply store has one, and that robot can be in the backroom depalletizing, cleaning, stocking shelves, checking inventory, just a huge range of things,” says Hurst. “That’s where the real value comes in.”

Ongoing progress in natural language processing also means robots could take guidance through voice commands. Programming a new task could be as simple as a supervisor saying, “Please mop the floor,” making it easier for robots to work alongside human colleagues.

But there are still safety concerns around heavy metal robots working side by side with humans, and there will be plenty of edge cases to contend with. Chris Atkeson, a professor at Carnegie Mellon University’s Robotics Institute, says the central challenge will be reliability. He used the example of a robot left to restock shelves overnight. The task might be done perfectly for months until a failure case emerges.

“Suppose the owner comes in one day and nothing’s on the shelves, everything’s on the floor. Suppose the place burns down,” Atkeson says. “Those are very expensive failures.”

Still, the rapid pace of progress on AI models gives reason to be optimistic. “If you’d asked me five years ago, I would have said, ‘Never gonna happen,’” Atkeson says. “But with large language models, we have made enormous progress in what I’ll call ‘common sense.’ Maybe we’re almost there.”